© 2023 British Car Club of Charleston. All Rights Reserved.

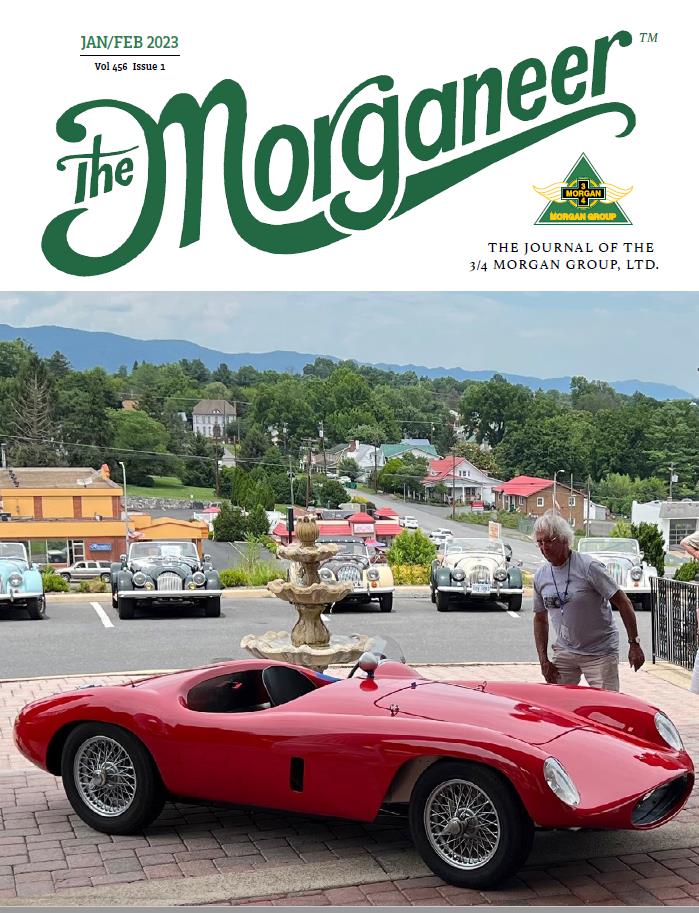

One of our members has made a remarkable car, years ago John Bigler started with the idea of putting a Devin body on a Morgan chassis and it is an incredibly good build. Here is a wonderful write-up, thanks goes to Morgan Malone of the Morgan 3/4 Group for granting permission to include a copy of their newsletter, The Morganeer. The issue opens with John’s car on the cover and has a great interview starting on page 10, along with some history of the car on page 13. I’ve been around Historic Racing cars for about 40 years, and what John has made is as close to a ‘Special’ built in 1960 as you will ever find – very well done, John!

Click on the picture to the right to download and read The Morganeer.

Click on the picture to the right to download and read The Morganeer.