© 2022 British Car Club of Charleston. All Rights Reserved.

Randy Dickinson's MGTD transmission

While the engine to Randy's MGTD is at the shop and while we look for pistons and rings, I decided to look into the transmission. When in fourth gear it would pop out of gear when you accelerated. When I removed the transmission top cover I could see two reasons. One was play in the 3-4th gear selector shaft. Under the three springs in the picture below are ball bearings. They ride along the three selector shafts and hold the shaft at certain places when the ball falls into a detent. When the transmission is put into 4th gear, the 3-4th selector shaft could be moved about a quarter inch. You can't see it until it is taken apart, but the detent must be elongated. The second visible problem is the 3-4th gear fork can be moved telling me there is excessive wear between the fork and selector striking dog. Hey, I didn't name it!

While the engine to Randy's MGTD is at the shop and while we look for pistons and rings, I decided to look into the transmission. When in fourth gear it would pop out of gear when you accelerated. When I removed the transmission top cover I could see two reasons. One was play in the 3-4th gear selector shaft. Under the three springs in the picture below are ball bearings. They ride along the three selector shafts and hold the shaft at certain places when the ball falls into a detent. When the transmission is put into 4th gear, the 3-4th selector shaft could be moved about a quarter inch. You can't see it until it is taken apart, but the detent must be elongated. The second visible problem is the 3-4th gear fork can be moved telling me there is excessive wear between the fork and selector striking dog. Hey, I didn't name it!

Below shows the three selector shafts

Below is the 3-4th gear selector shaft. The two outer indents should look the same. The right one is elongated causing excessive play in the 4th gear position. This was part of the reason why it poped out of 4th gear. I could not find anyplace that sells this part.

Below is the 3-4th gear selector fork. The radial wear shown should not be there.

This part is not available from Moss Motors. A used one is available from Abingdon Spares for $95.95.

This part is not available from Moss Motors. A used one is available from Abingdon Spares for $95.95.

Below shows a closeup of the 3-4th gear selector striking dog. The left side is straight whereas the right side is tapered. The width of the two areas shown should be the same.

This part is available from Moss Motors for $275.

A used one is available from Abingdon Spaces for $95.

This part is available from Moss Motors for $275.

A used one is available from Abingdon Spaces for $95.

A transmission gaskget set is $27.95 at Abingdon Spares.

Shaft seal, $8.45 at Abingdon Spares.

New bearings are $33.95 at Abingdon Spares and $24.95 at Abingdon Spares.

Shaft seal, $8.45 at Abingdon Spares.

New bearings are $33.95 at Abingdon Spares and $24.95 at Abingdon Spares.

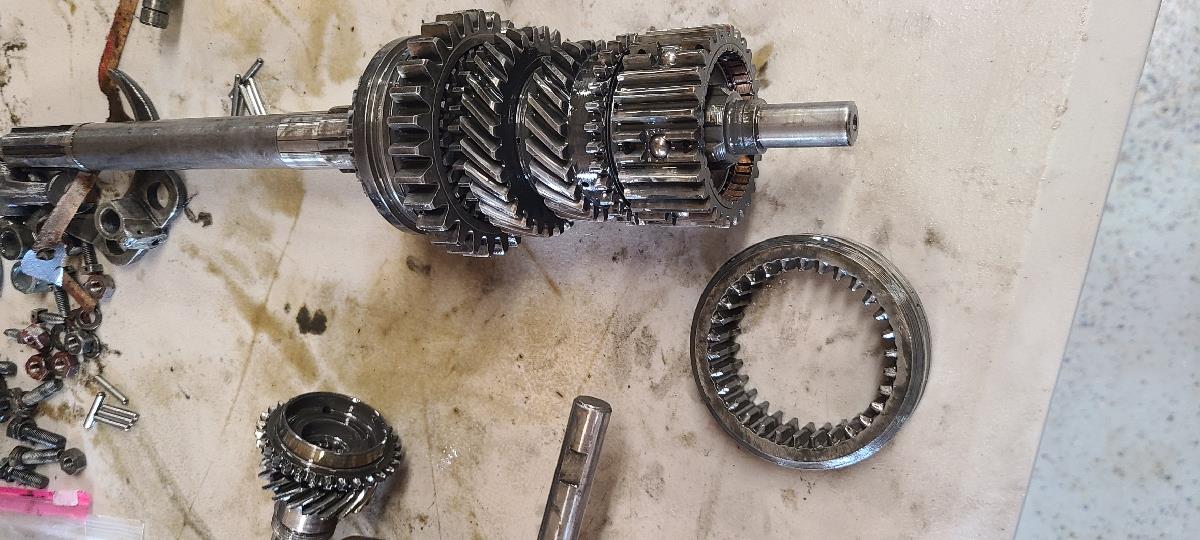

I next removed the flange on the end of the transmission. I then removed the housing on the end. Next I removed the bearings on either end of the transmission. Fortunately they are not pressed in to screwdrivers, hammers and patience got them out. Not to remove the gears. They come apart into two pieces but they can't be removed out the top or the end holes because the lower gear trane is in the way. On the left side of the transmission in the picture below, you can see the end of the shaft holding all the lower gears in place. With a foot long 3/8" socket extension, I tapped on the shaft until it came out the other side. All the gears then dropped to the bottom giving enough roof to remove the main gears.

The two parts are seperated and the left side removed from the top. When they are seperated, needle bearings inside the left gear set will probably fall out, which they did. They are cirecled in red in the picture below. Next, the right side is carefully fed out the top.

The two parts are seperated and the left side removed from the top. When they are seperated, needle bearings inside the left gear set will probably fall out, which they did. They are cirecled in red in the picture below. Next, the right side is carefully fed out the top.

The problem striking dog is simply slide off the end of the gears, shown in the picture below.

Since this part is not available, I will try filling the right indent with weld. The I will grind the weld to the proper detent shape. My concern with this is when you weld one side of a rod, it tends to bend. Also, the small pin in the side of the shaft in the picture above must move freely after the welding is done.

The good news is that all the gears look good as do the bearings.